On average, approx. 6000 kWh of electricity and 29,000 kWh of heat are consumed per bed per year, corresponding to a heat demand of 6,960,000 kWh p.a. and an electricity demand of 1,440,000 kWh p.a. This high energy demand also results in high energy costs.

Application: market environment.

Modernization in the healthcare sector.

- more than 80 % of existing systems are operated inefficiently

- energy centers are rarely a management focus in hospitals

- 2100 hospitals in Germany (total expenditure € 60 billion, of which energy accounts for € 1.5 billion)

Application: object.

Modernization in the healthcare sector.

A hospital.

In order to meet the very high energy demand of the building in an economical and environmentally friendly manner, the old system should be modernized using advanced systems technology.

Application: requirements.

Modernization in the healthcare sector.

Requirements:

- extremely large output range for the production of heat and power

- remote monitoring or BMS connection

- operating cost savings

It is common for a hospital to have around 240 beds.

Use of steam boiler systems.

As an alternative, gas steam boiler systems can be used to provide energy in hospitals. The steam that is generated is used for kitchens and the central sterilization department, for humidification of the air conditioning system and for the laundry.

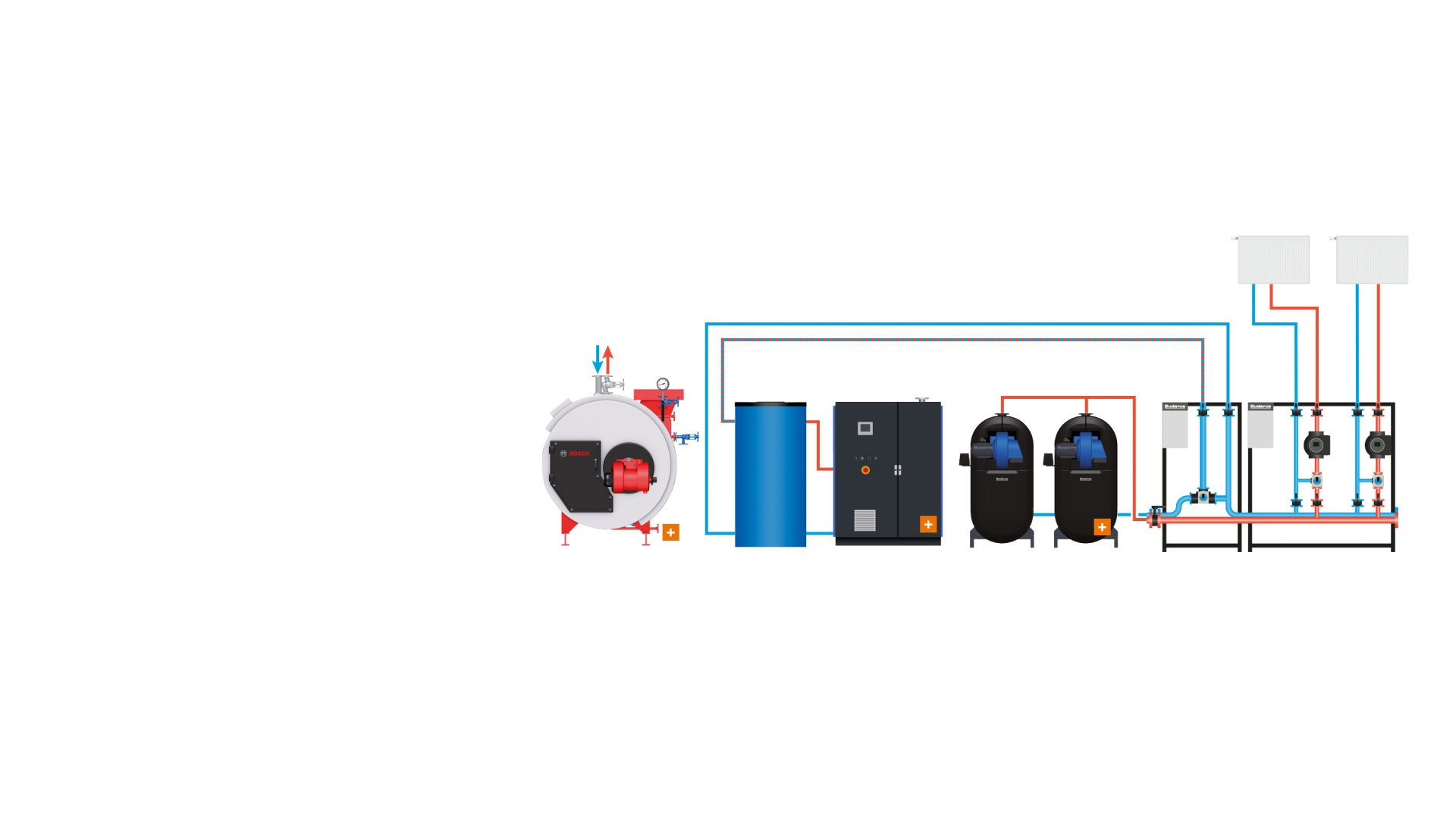

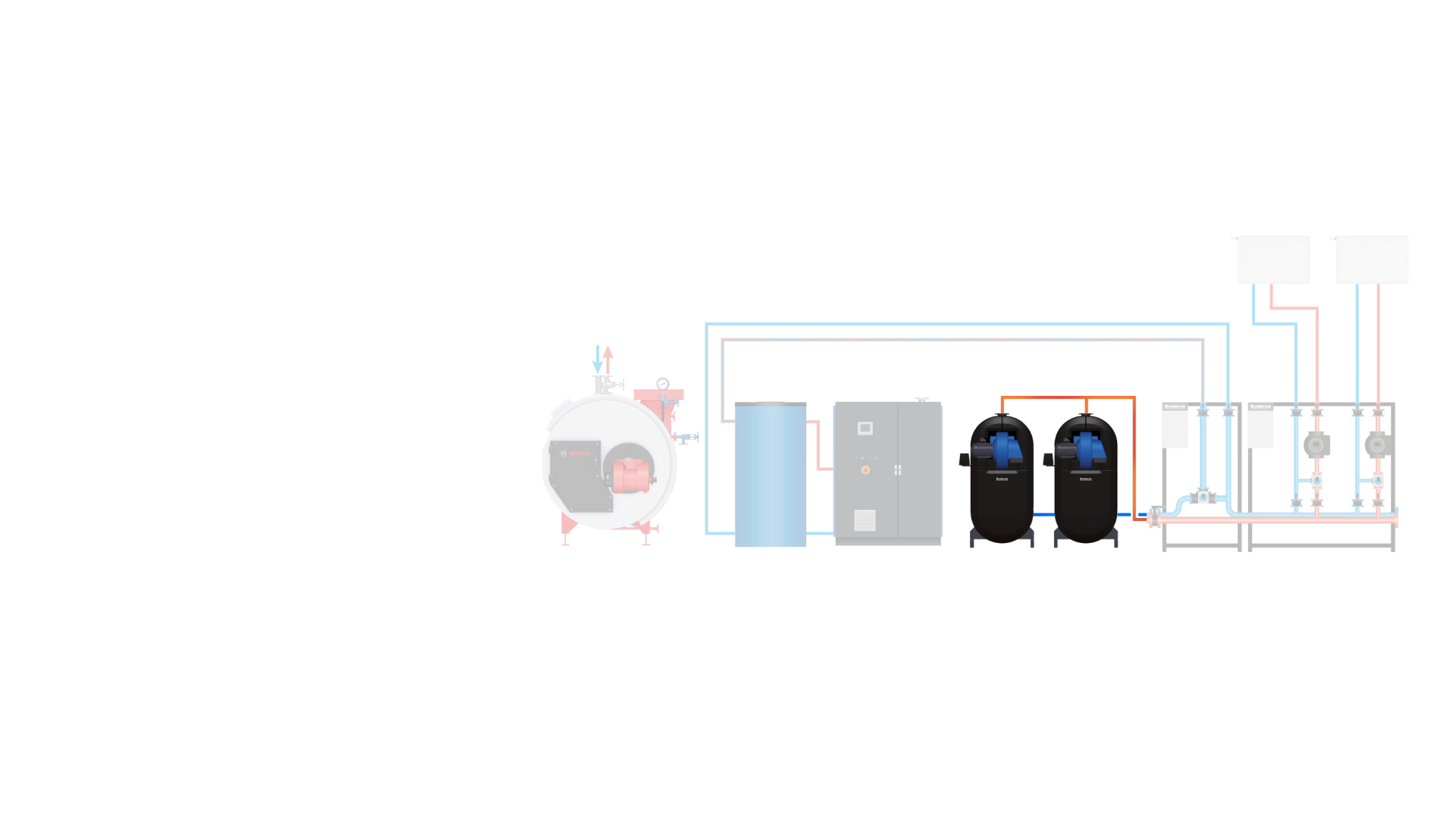

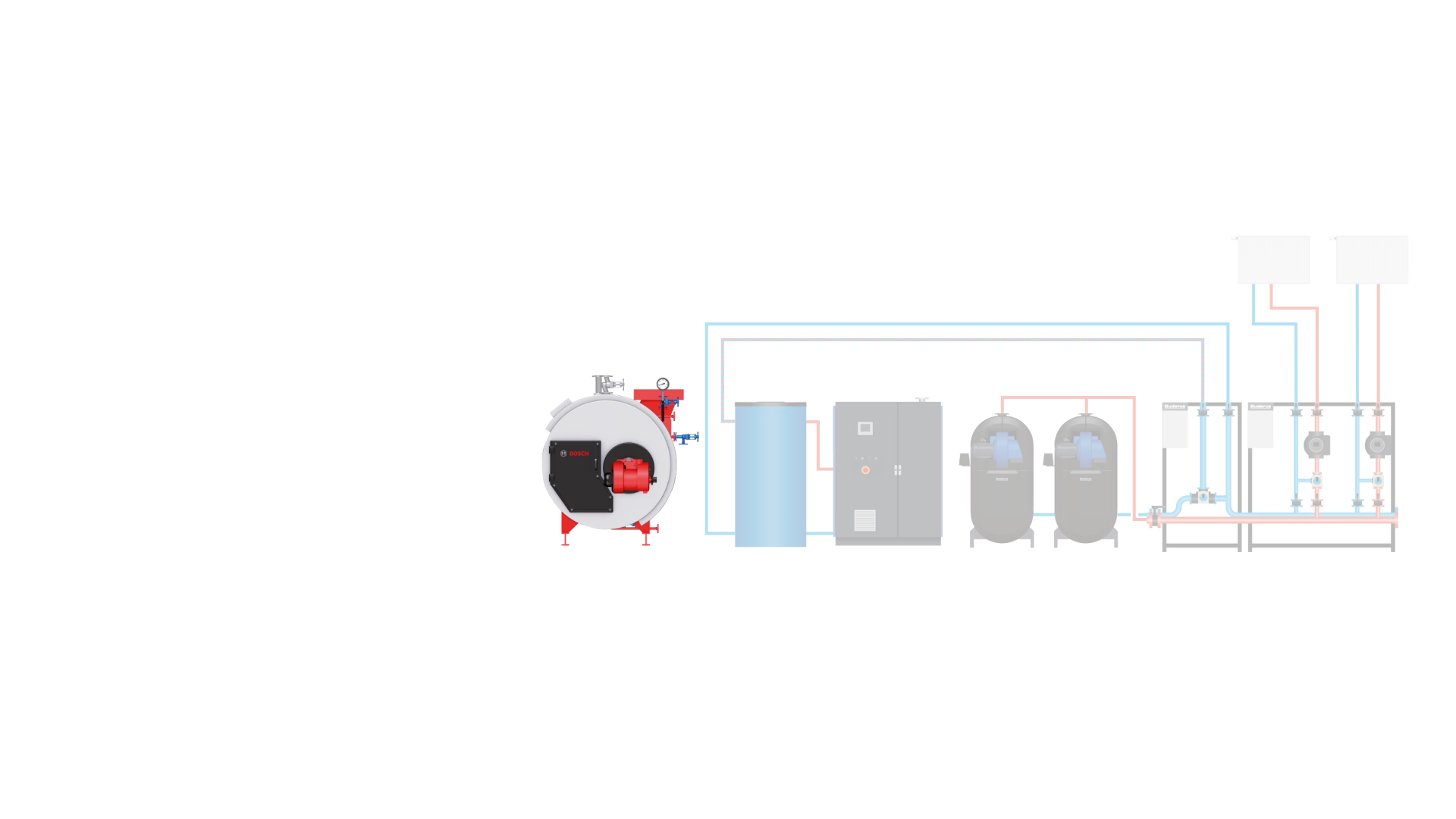

System: standard system.

Logano plus SB745 cascade oil/gas condensing boiler

- efficient and simple to install oil/gas condensing boiler

- partial load efficiency of up to 98 %

- low emissions

Logamatic 5311 control system:

- modular, digital control unit for medium to large boiler systems

- high quality, robust 7” touchscreen

- IP and Modbus connectivity

Logaflow HSM plus:

- available pre-assembled

- compact design for quick installation

- fully wired control panel

System: standard system.

Loganova EN140 CHP module

- reduced energy costs thanks to combined generation of power and heat

- high on-site consumption as a requirement for high economic efficiency

- statutory feed-in tariff, subsidy and tax relief

Logamatic 5000 modular control system:

- bidirectional communication with CHP module via Modbus RTU interface (RS485)

- visualization of all important CHP unit operating states and data

- carries out buffer storage tank management and CHP module control

System

Extension stage 1:

heat generator management.

System: extension stage 1.

Heat generator management.

Control panel system:

- safeguarding the operating conditions of all system components

- intelligent control strategies for heat generators

- modular extendibility and flexible application in any environment

System: extension stage 1.

Heat generator management.

System benefit:

An integral control panel system ensures the efficient and intelligent interaction of all system components.

System

Extension stage 2:

steam boiler.

System: extension stage 2.

UL-S universal steam boiler

- high efficiency due to three-pass technology, integral economizer and effective thermal insulation materials

- high pressure stability and steam quality with intuitive PLC-based boiler control

- suitable for all burner systems

System: extension stage 2.

UL-S universal steam boiler.

System benefit:

The UL-S steam boiler is delivered as standard with integral economizer (additional flue gas heat exchangers). This ensures a high level of energy utilization. The result is a fuel saving of up to 7 %. It also means reduced demand for resources and therefore lower emissions. A complete steam boiler system includes not just a steam boiler but also a wide range of system components which help to achieve further energy savings and lower costs and emissions.

Reference system at Winsen hospital.

The system for steam provision, which was installed 38 years ago, has been successfully modernized. The hospital’s technical directors, Dipl.-Ing. Torsten Riemer and Thorsten Holz, are very pleased: “The modernization instantly achieved natural gas savings of around 15 %. Reduced CO2 emissions mean we are also making an important contribution towards climate protection.”

System

Extension stage 3:

System accessories.

System: extension stage 3.

System accessories.

- durable products

- perfectly matched to Buderus products

- extensive choice for a variety of systems

System: extension stage 3.

System accessories.

System benefit:

Not just a manufacturer of high quality products for the entire heating equipment sector, Buderus is also a wholesaler. We sell everything relating to the heat generator, as well as all products for heat distribution and heat transfer.

Logano plus SB745 cascade oil/gas condensing boiler:

- ensures optimum modulation ranges and modernization without interrupting hospital routine

- compared with 15-20 year old boilers, optimum settings mean energy savings of more than 10 % p.a., or up to 25 % with older appliances

- partial load efficiency of up to 98 %

- low emissions

Loganova EN140 CHP module:

- payback periods of just 1.7 years (hospital with 240 beds, base load sizing)

- statutory feed-in remuneration, subsidy and tax relief

- high on-site consumption as a requirement for high economic efficiency

UL-S universal steam boiler:

- automatic start-up, standby and shutdown device SUC

- fast commissioning thanks to preset boiler control parameters

- straightforward on-site wiring through fully wired connections

- high efficiency due to three-pass technology, integral economizer and effective thermal insulation materials

- high pressure stability and steam quality with intuitive PLC-based boiler control

- suitable for all burner systems

Networking.

Buderus Control Center Commercial

- 1 : 1 touchscreen display in the browser for intuitive remote control

- user level parameterization

- display of latest operation and error messages

Networking.

Buderus Control Center CommercialPLUS

- system overview with status indicator

- complete parameterization, including service level

- data recording with graphical display

Networking.

Modbus communication.

The Logamatic 5000 Modbus serial interface provides you with numerous data points providing, for example, graphic display of your Buderus heat generator in a BMS application showing the most important parameters.

Service.

ProDelivery app.

- transparent Germany-wide shipment tracking of Buderus deliveries and returns

- information on the delivery status directly in the app without having to contact the branch by phone

- considerable time savings, flexible and convenient operation due to clear layout

- large number of additional functions such as delivery history, PDF download of delivery note, parking approval, and much more.

Service.

Here for you 24/7/365.

- from consulting on project engineering right through to commissioning, maintenance and modernization, the focus is on the entire lifecycle of the system

- protected remote access and a 24/7 service and spare parts hotline round off the service portfolio

Service.

Comprehensive range of services.

Bosch offers a comprehensive range of services throughout the lifecycle of the system.

- sizing/support

- installation/wiring

diagrams - BIM/3D data

- commissioning

- operator training

- optimization

- remote diagnosis and

programming - troubleshooting

- 24 h standby

- 24 h hotline for spare

parts service

- acceptance tests

- power plant identification

system

- maintenance services

- recurrent inspections

- modernizations

- system analysis

- efficiency consulting

- repairs

- modifications

- repowering